- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

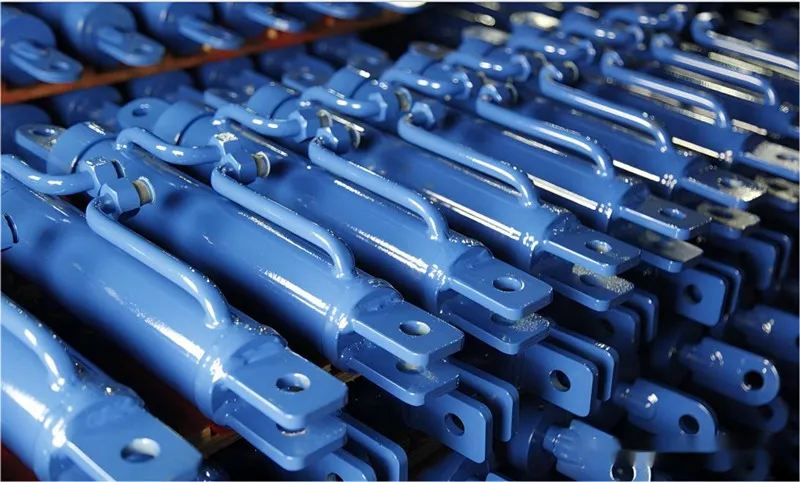

Kepiye Mbusak lan Nglumpukake Silinder Hidrolik lan Apa Pancegahan sing Kudu Ditindakake?

2024-12-30

Pembongkaran lan perakitan silinder hidrolik minangka proses sing mbutuhake operasi sing ati-ati lan mbutuhake sawetara langkah lan pancegahan. Kanggo njamin safety lan efisiensi proses disassembly lan perakitan, sampeyan kudu ngetutake langkah-langkah sing bener.

Preparation Disassembly

1. Cool Down Full

Silinder hidrolik bakal ngasilake suhu dhuwur sajrone operasi. Sadurunge mbongkar silinder hidraulik, sampeyan kudu ngenteni silinder hidraulik rampung adhem sawise mandhegake peralatan sing mlaku. Yen disassembly banget awal, bisa nimbulaké bebaya safety.

2. Siapke Piranti

Siapke alat sing dibutuhake, agen pembersih, lenga pelumas, spidol, gombal, sikat lan wajan lenga (kanggo cairan limbah, agen pembersih, lan lenga pelumas). Sadurunge disassembly, priksa tampilan silinder kanggo ndeleng yen ana nyandhang, teyeng, etc., supaya operasi diangkah bisa dileksanakake sak disassembly.

3. Ngresiki Silinder Hidrolik

Sadurunge mbongkar silinder hidrolik, ngresiki rereget ing permukaan silinder supaya ora mlebu ing silinder lan mengaruhi panggunaane. Ing wektu sing padha, priksa manawa wilayah kerja resik lan rapi. Iki ora mung kondusif kanggo njaga kebersihan mesin, nanging uga nyuda gangguan lenga lan bledug.

Langkah-langkah Disassembly

1. Copot joints ing welingan lenga lan stopkontak, lan banjur saluran lenga ing silinder supaya lenga outflow sak disassembly.

2. Copot konektor. Gunakake alat kayata wrenches utawa screwdrivers kanggo misahake pipa lan konektor saka silinder hydraulic. Ati-ati supaya ora kena langsung nganggo palu supaya ora ngrusak mesin.

3. Remove the end cover: Use the corresponding tools to remove the end cover. Be careful not to damage the end cover and the gasket to avoid damaging the cylinder or other parts during the disassembly process.

4. Copot rod piston: Copot rod piston saka silinder. Yen perlu, copot segel lan O-ring ing arah ngarep lan mburi rod piston.

5. Piston piston: Copot piston saka silinder. Yen ana sambungan sing kenceng ing antarane piston lan silinder, pilih cara istirahat sing cocog adhedhasar kahanan kerja, kayata nggunakake roda tangan, palu, lsp.

6. Copot awak silinder: Yen awak silinder kudu dibusak, nggunakake disassembler kanggo mbusak awak silinder.

7. Copot bagean cilik kayata segel lan O-rings nang silinder.

Precautions For Disassembly And Assembly

1. Sadurunge disassembly, sirkuit hydraulic kudu depressurized. Yen ora, nalika sambungan pipa lenga disambungake menyang silinder lenga wis loosened, lenga-tekanan dhuwur ing sirkuit bakal semprotan metu cepet. Nalika depressurizing sirkuit hydraulic, pisanan loosen handwheel utawa meksa ngatur sekrup ing tutup kebanjiran, etc. kanggo mbongkar lenga meksa, banjur Cut mati sumber daya utawa sumber daya kanggo mungkasi piranti hydraulic saka mlaku.

2. Nalika disassembling, nyegah karusakan ing Utas ndhuwur rod piston, thread port lenga, lumahing rod piston, tembok utama saka lengen silinder, etc. Supaya kanggo nyegah mlengkung utawa ewah-ewahan bentuk saka bagean langsing kuwi minangka rod piston, nggunakake pamblokiran kayu kanggo ndhukung imbangan nalika manggonke.

3. Rampungake disassembly ing urutan. Struktur lan ukuran macem-macem silinder hidrolik beda-beda, lan urutan disassembly rada beda. Nanging, iku umume perlu kanggo disassemble ing urutan draining lenga, njabut sirah silinder, lan njabut piston utawa rod piston. Nalika mbongkar sirah silinder, alat khusus kudu digunakake kanggo kunci utawa ring sworo seru sambungan tombol internal, lan shovels warata dilarang; kanggo tutup mburi jinis flange, ngawut-awut kudu digunakake kanggo push metu, lan hammering utawa prying hard ora diijini. Nalika piston lan rod piston angel ditarik, goleki alesan sadurunge disassembling, lan aja dipeksa metu.

4. Sadurunge lan sawise disassembly, nyegah bagean saka silinder hydraulic saka kang ono racune dening bledug lingkungan lan impurities. Disassembly kudu ditindakake ing lingkungan sing resik sabisa, lan kabeh bagean kudu ditutupi kain plastik sawise disassembly.

5. Sawise disassembly, kasebut kanthi teliti, mriksa kanggo nemtokake bagean sing bisa terus digunakake, bisa digunakake maneh sawise ndandani, lan kudu diganti.

6. Kabeh bagean kudu kasebut kanthi teliti, di resiki sadurunge reassembly.

7. Correctly install the sealing devices in various places: When installing the O-ring, do not pull it to the extent of permanent deformation, and do not roll it while installing it, otherwise it may leak oil due to distortion. When installing Y-shaped and V-shaped sealing rings, pay attention to their installation direction to avoid oil leakage due to reverse installation. The lip of the Y-shaped sealing ring should face the oil cavity with pressure, and pay attention to distinguish whether it is for shaft or hole. The V-shaped sealing ring is composed of supporting rings, sealing rings and pressure rings of different shapes. When the pressure ring presses the sealing ring, the supporting ring can make the sealing ring produce a shape and play a sealing role. When installing, the opening of the sealing ring should face the pressure oil chamber; when adjusting the pressure ring, it should be limited to no oil leakage, and it should not be pressed too tightly to prevent excessive sealing resistance. If the sealing device cooperates with the sliding surface, it should be coated with an appropriate amount of hydraulic oil during assembly. All O-rings and dust rings after disassembly should be replaced.

8. Sawise piston lan rod piston nglumpuk, ngukur coaxiality lan straightness liwat kabeh dawa kanggo ndeleng yen lagi metu saka toleransi.

9. Sawise perakitan, mesthine ora ana rasa macet lan resistensi sing ora rata nalika gerakan piston.

10. When the hydraulic cylinder is installed on the main engine, a sealing ring must be added between the inlet and outlet joints and tightened to prevent oil leakage.

11. Sawise perakitan minangka dibutuhake, sawetara gerakan reciprocating kudu dileksanakake ing kurang meksa kanggo mbusak gas ing silinder.

Ing Ringkesan

Disassembling and assembling a hydraulic cylinder demands caution and follows specific steps. Before disassembly, let the cylinder cool, prepare tools, and clean it. The disassembly steps include draining oil, removing connectors, end covers, piston rod, piston, and cylinder body, along with small internal parts. Precautions include depressurizing the hydraulic circuit first, protecting parts from damage, disassembling in sequence, maintaining a clean environment, inspecting and cleaning parts, correctly installing sealing devices, checking coaxiality and straightness, ensuring smooth movement, adding sealing rings at connections, and performing low-pressure reciprocating motions to remove gas.